PerMix Mayonnaise Production

Mayonnaise Production Equipment Sizing & Info

Best in Innovation • Best In Performance • Best In Quality • Best In Price • Best In Warranty

Issues Eliminated With PerMix In Mayonnaise Production

PerMix Perfects Mayonnaise Production

So you have it as a reference, here is some info in regards to production.

The PVC-500 which will produce a 125 gallon batch every 8 to 12 minutes depending on type of mayo. The main unit is nicely equipped enough to complete the task. The options are mostly if you want to semi-automate the ingredients further, but not needed. With this size you will do two 55 gallon drums every 12 minutes, or a pallet every 24 minutes. Totaling 3 pallets every hour or 24 pallets a day, which

there are 22 pallets in a truckload. These times take into consideration loading & discharge also. A truck load full of mayo is typically between $15,000 to $18,000 in value for an economical brand and higher in a premium brand, pulling in up to $22,000 a truckload. A small manufacturer with a small customer list will do 2 trucks a week. Medium size facility will do 4-6 trucks a week of just mayonnaise. When I calculate ROI, it is always on 2 trucks a week for the PVC series. Also, just more info, in a normal production facility that does not process under vacuum, they have an average of 8 drums per truck that “break” and are bad. “Breaking” is when the mayonnaise goes to packaging and the oil separates and floats on top. That is called “breaking” and is not usable.

A single PVC-1000 can do 2 truckloads a day, and so on.

So, when you take a look at ROI, it is between 3 to 5 months, sometimes 2 months Mayo is the main

base for many salad dressings such as Thousand Island, Blue Cheese, Creamy Italian, and more…

PerMix’s Approach To Mayonnaise Production Benefits

Increase Mayonnaise Production

Depending on size, you can make from 1 truckload of mayonnaise per day (88 drums / 22 skids) to 8

truckloads per day with just one unit. Various models are available to meet demands.

Decrease Mayonnaise “Breaking”

Eliminate “breaking” and lower the cost of rejects & reworks. Our “All-In-One” vacuum mixer processor

allows for maximized production with decreased risk of bad batches.

Decrease Labor

PerMix’s ability to engineer our universal vacuum mixer processor allows for decreased labor, allowing

for a quick ROI.

Ease of Use

Mayonnaise production made easy with our “All-In-One” design, simplifying production.

Extended Shelf Life

Shelf life is everything when we talk about profit margins and with the use of vacuum, shelf life is

maximized as well as food safety protocols. Something your SQF Practitioner will love.

Increased Quality

Batch control is maximized as the “All-In-One” concept minimizes inconsistencies in batch processing and allows for better control.

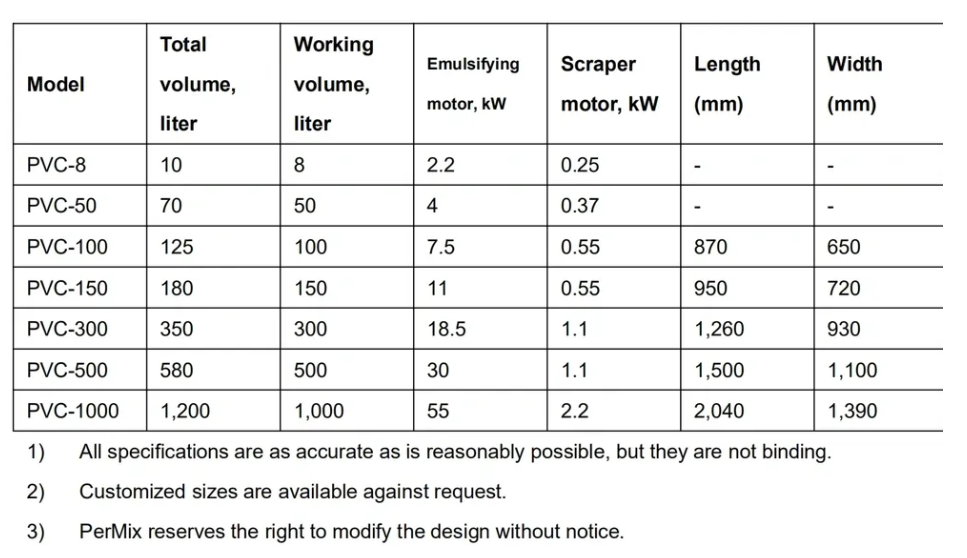

PerMix PVC Universal Emulsifying Mixer Sizing

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.